The Problem

Understanding how dislocations (line defects in the crystal structure) occur when 3D-printing metals has been unclear to materials scientists.

Understanding how dislocations (line defects in the crystal structure) occur when 3D-printing metals has been unclear to materials scientists.

A multi-platform approach to track how dislocations form and evolve.

Understanding when and how dislocations form in 3D-printed metals could support stronger, more reliable parts used in medical implants and airplanes, ensuring safety, durability, and performance in critical applications.

Professor Tao Sun

A major challenge in metal 3D printing is controlling the microstructure, which determines a material’s mechanical properties. One key factor is the formation of dislocations: defects in the crystal structure that develop during the printing process. These defects can significantly impact strength, toughness, and ductility. Understanding how dislocations form and their behavior is essential for improving the reliability of 3D-printed parts.

“By understanding when and why dislocations occur, we can better control them,” said Tao Sun, associate professor of mechanical engineering at Northwestern Engineering.

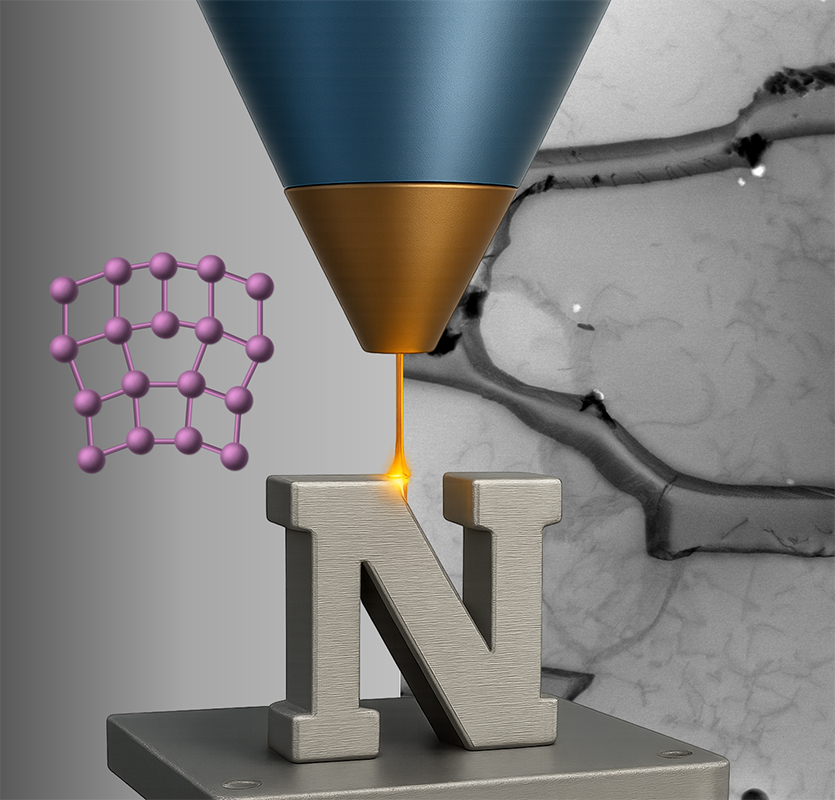

New research from Sun is uncovering new insights in metallic dislocations. In the study, Sun combined synchrotron X-ray diffraction with neutron diffraction, multi-physics simulation, and electron microscopy to track how dislocations form and evolve when printing 316L stainless steel, a commonly used alloy in additive manufacturing.

The findings could improve future 3D printing techniques, which build objects layer by layer based on digital designs, offering new approaches to manufacturing across industries. Understanding how dislocations forms could support the development of new alloys and the creation of parts in more complex shapes. This is especially relevant in sectors like aerospace, healthcare, and defense, where materials are required to perform in demanding environments.

“For the first time, we’ve quantitatively measured dislocation density and its changes during the rapid cooling process in fusion-based additive manufacturing,” Sun said. “This study will inspire the research community to conduct similar experiments on novel and complex alloy systems.”

Sun reported his findings in “Evolution of Dislocations During the Rapid Solidification in Additive Manufacturing,” published May 20 in Nature Communications.

Tao SunAssociate Professor of Mechanical Engineering

Among its findings, the team’s data showed that high dislocation densities are primarily generated during the steel’s solidification, when a liquid cools down and suddenly turns into two solid substances at the same time, all at one specific temperature. This contradicts prior assumptions that attributed them solely to residual stresses introduced after solidification.

The new study offers a different explanation.

“Our findings reveal the critical role of the eutectic reaction in initially generating high dislocation densities,” Sun said. “We also identify the competing effects of annealing and stress on dislocation evolution during the subsequent cooling and thermal cycling processes.”

The team also reported that different stages of the printing process play opposing roles.

Thermal cycling, when a material is repeatedly heated and cooled and inherent in 3D printing processes, may recover some dislocations. Meanwhile, residual stresses – leftover forces locked inside a material after it’s been shaped, heated, or cooled – could regenerate them. The net result is a complex and dynamic evolution of defect structures inside the material.

“Dislocation structures are critical microstructural features that bridge printing parameters with the performance of final additive manufacturing products,” Sun said. “Understanding and controlling these unique dislocation structures will not only advance knowledge of structural dynamics under non-equilibrium conditions, but also accelerate the industrial adoption of additive manufacturing techniques for fabricating structural components.”

The findings may impact the design of future alloys that are stronger and less prone to failure. For example, modifying the composition of stainless steels by adjusting the chromium and nickel ratio or adding aluminum can affect the solidification path. This subsequently influences both the formation of dislocations and the development of residual stress.

The researchers also highlighted implications for multiphase alloys. Stress distribution is uneven in systems with brittle phases. Differences in thermal expansion and grain orientation can lead to cracking and other forms of failure. Sun’s work suggests that careful control of thermal expansion and interface cohesion in eutectic structures can reduce the likelihood of these issues.

Sun and his team’s next phase of research will involve process innovation and alloy design. They plan to apply their approach to a broader range of compositions and printing conditions.

“We will continue to explore these research avenues to refine process innovation and alloy design, applying what we have learned to improve both the quality and functionality of 3D-printed metals,” Sun said.